Home | What is AgiLAB

AgiLAB

Process Innovation

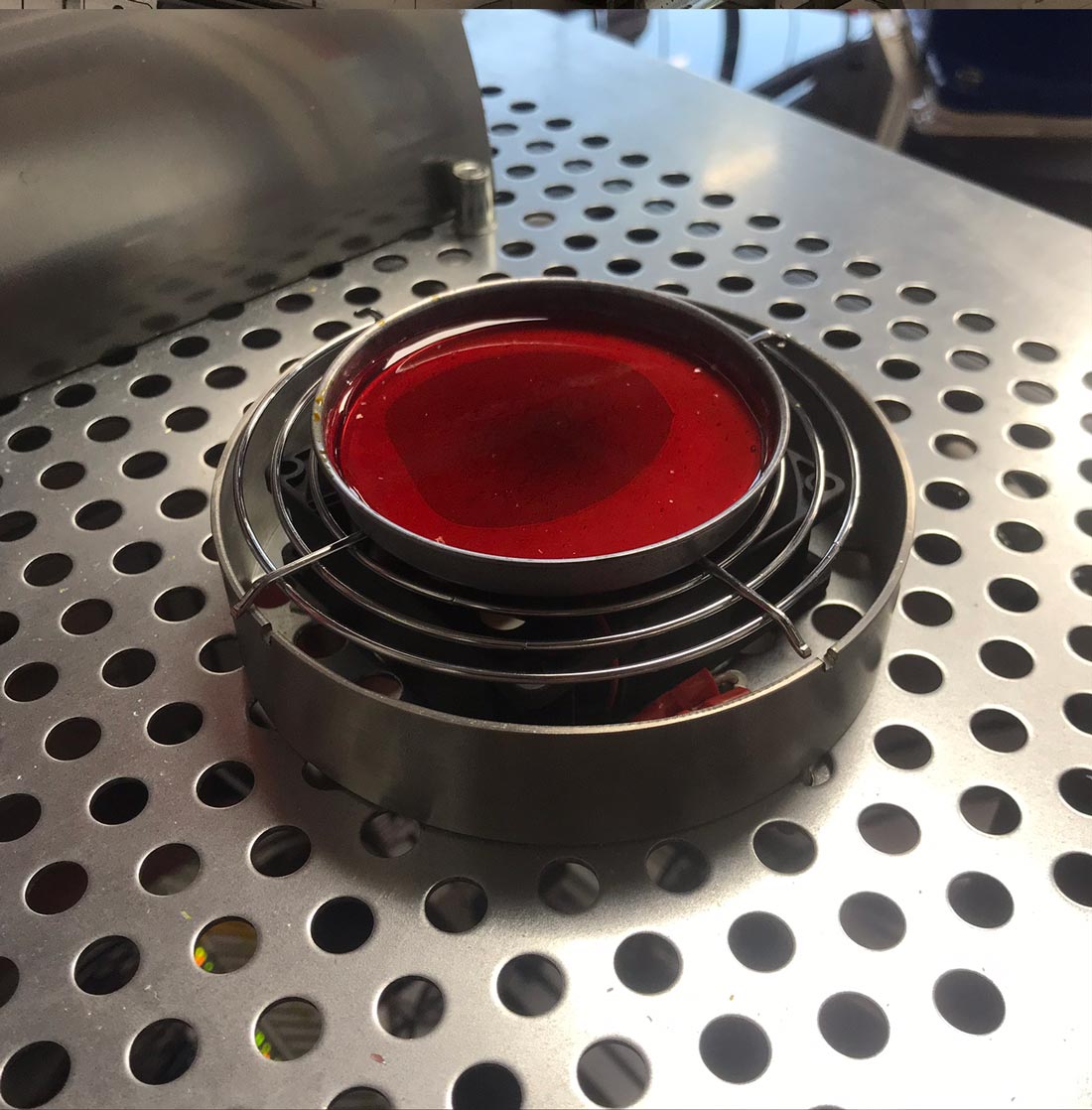

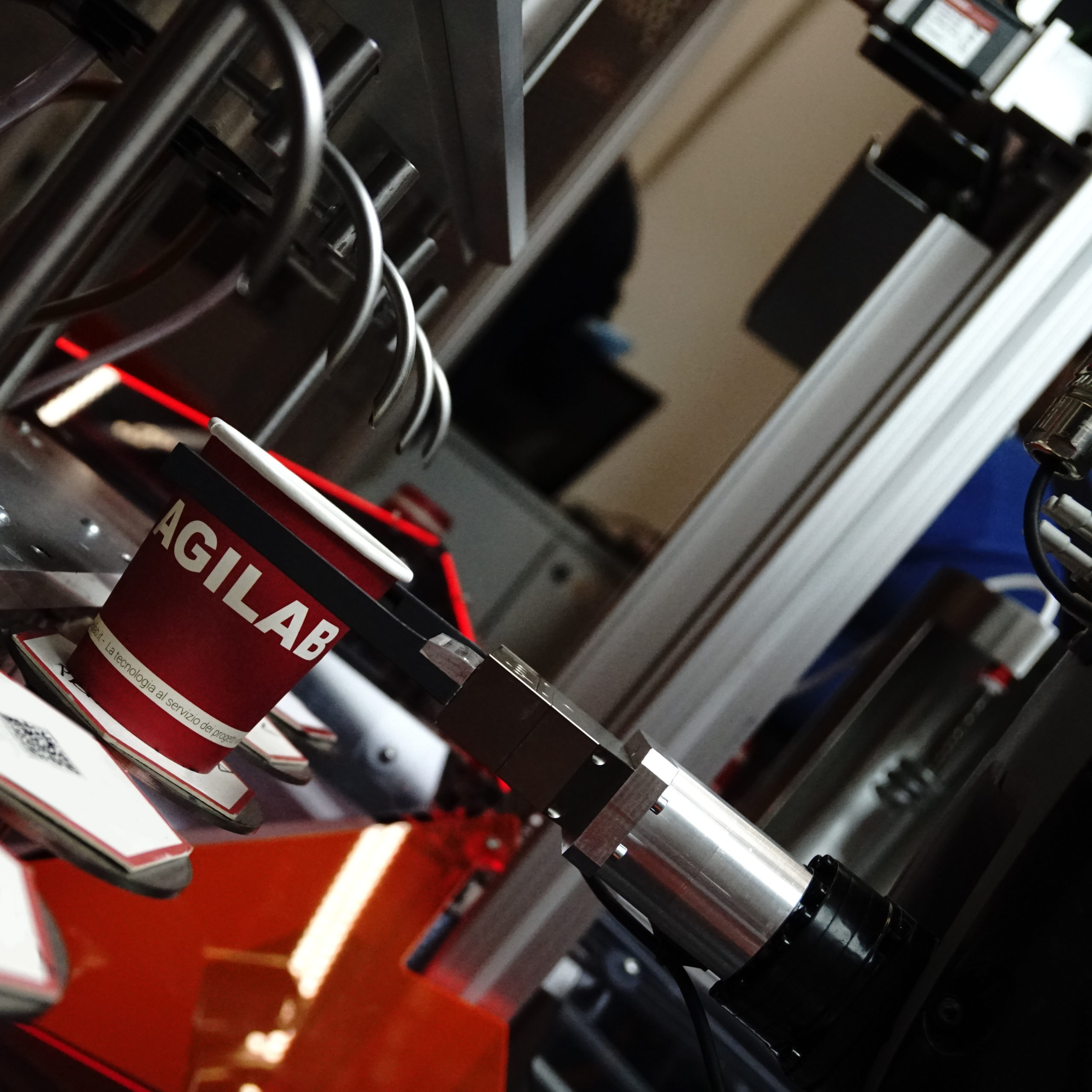

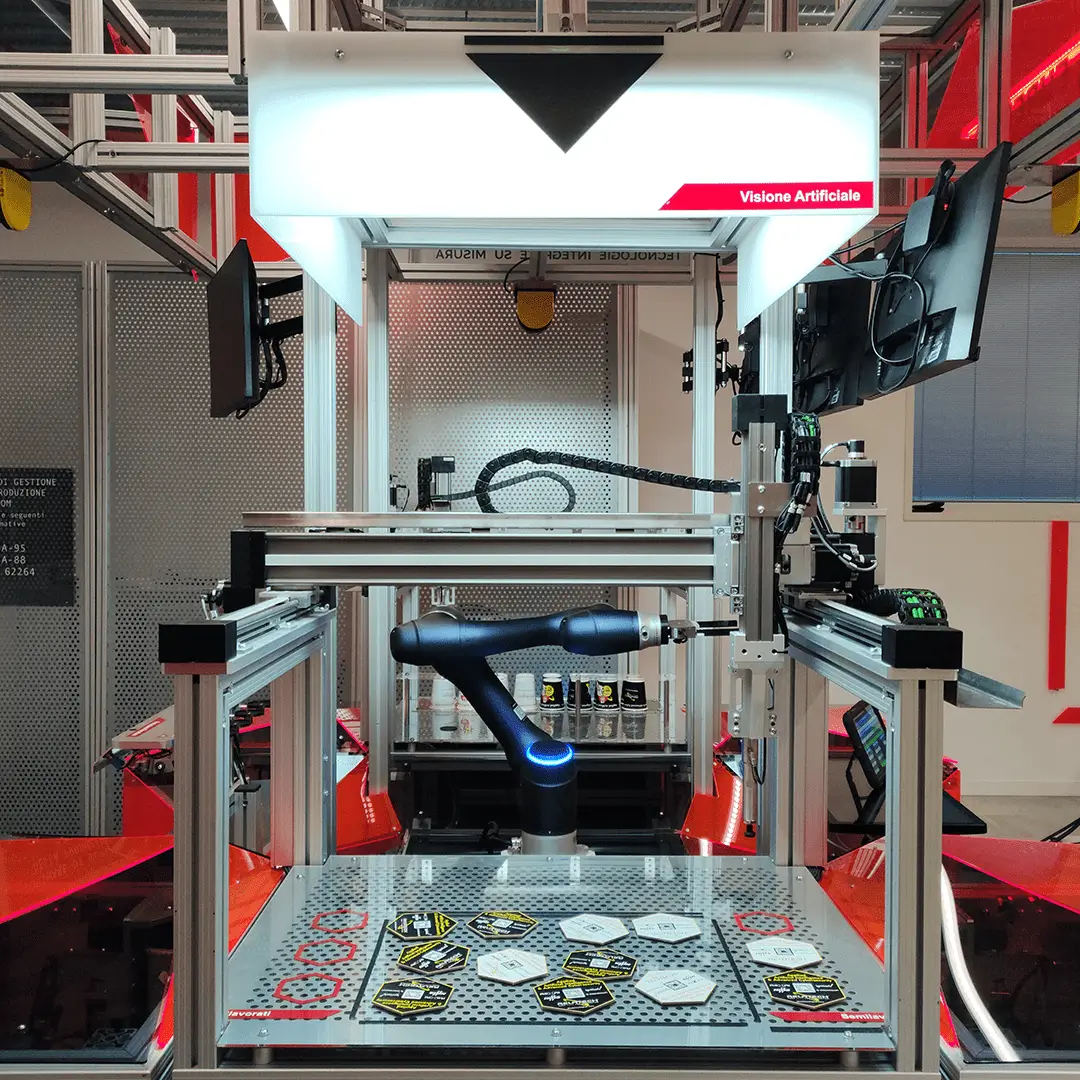

AgiLAB serves as both a laboratory and showroom, demonstrating Eureka System’s expertise in Automation

In recent years, manufacturing companies have focused on digitizing production processes, a crucial factor ensuring the continuity of many industrial realities.

Digitizing production processes allows companies to manage operations involving people, machines, and resources more efficiently through customized automated systems. It optimizes every stage of the supply chain and demands flexibility and quick responses to environmental and societal changes.

AgiLAB aims to emulate the production process of a Smart Factory on a reduced scale to help the industry, especially the manufacturing sector, understand a wide range of innovative technologies.